- Project name: Phuoc An bridge connecting Phu My town, Ba Ria – Vung Tau province with Nhon Trach district, Dong Nai province.

- Package: Construction of approach bridge from pier T40-T41 to pier T62

- Location: Nhon Trach district, Dong Nai province

- Employer: Cai Mep – Thi Vai Port Area Transport Project Management Board

- Main contractor: VNCN Engineering Construction and Investment JSC. (VNCN E&C)

- Type of work: Transport work

- Class of work: Special

- Contract value: 527 billion VND

- Implementation period: 1,077 days

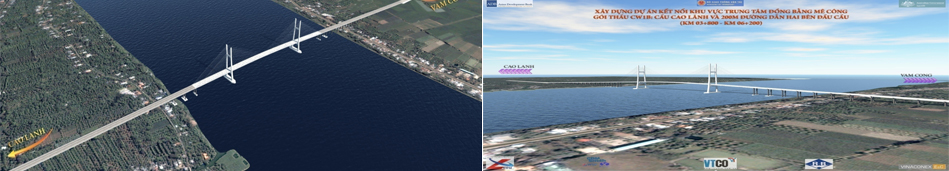

With objective to step by step form a complete transport network in the Southern major economic zone, contribute to the socio-economic development of the region, and in order to promote the efficiency of Cai Mep – Thi Vai sea port, the investment in construction of Phuoc An bridge is an important item to connect the Cai Mep – Thi Vai inter-port road with inter-region expressways in the South and the North – South expressway.

Phuoc An bridge is a major transport project, a special-class transport work, of which the People’s Committee of Ba Ria – Vung Tau province is the competent authority, has a high investment scale with total length of about 4.3 km. In which, the bridge part is 3.5 km, approach road on the alignment is 247 m, road connecting to Phuoc An port is 617.34 m. The construction value is about 3,834 billion VND. The project includes 5 main civil work packages: Package No. 38 Construction of approach bridge from the beginning of the alignment to pier T36-T37; Package No. 39 Construction of main bridge from pier T37 to pier T40; Package 40 Construction of approach bridge from pier T40 – T41 to pier T62; Package No. 41 Construction of approach bridge from pier T62 to abutment M75 and approach road; Package No. 42 Construction of asphalt concrete and lighting of the entire bridge.

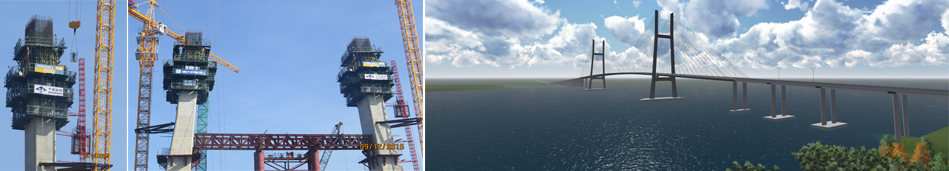

VNCN E&C is the contractor of Package No. 40: “Construction of approach bridge from pier T40 – T41 to pier T62 under Phuoc An bridge connecting Phu My town, Ba Ria – Vung Tau province with Nhon Trach district, Dong Nai province”.

* Project area: Section from Km20+303.5 to Km21+817.34. In which:

+ Starting point: pier T40 at Km20+303.5 (starting point of super T girder span of Phuoc An approach bridge in Nhon Trach district, Dong Nai province, erected on pier T40 of the main bridge).

+ Ending point: Km21+817,34 (The ending point connecting with the road to Phuoc An port) Project station.

+ Total length: about 2,174.84 m

* Construction scale

Phuoc An bridge shall have breadth of B = 23.5m according to the scale of 04 motorized lanes (lane breadth 3.5m) and 02 mixed lanes, and design velocity of 70km/h.

– Applicable technical standard frame: According to Decision No. 01/QD-UBND dated 04/01/2022 of the People’s Committee of Ba Ria – Vung Tau province, the approved scale and technical standards of Phuoc An bridge.

– The road class and the design velocity are corresponding to the Cai Mep – Thi Vai inter-port road: The main road is designed in accordance with standards for urban road as per TCXDVN 104:2007 with design velocity V=70km/h. The required elasticity modulus E ≥ 173Mpa.

- – Pre-stressed RC Super T girder, cast-in-situ bridge deck. Span outline: (39.1+21×40)m, continuous thermal plate connection.

- – Bridge cross-section: Breadth B=23.5m consisting of 10 super T girders placed at 2.35m interval; Girders are placed vertically, the 2% cross gradient and super-elevation shall be created by gradient of pier cap.

- – Pre-stressed RC Super T girder, girder height h=1.75m from pier T40 to pier T62, girder length L=38.2m. Girders are connected by cast-in-situ RC cross beams at two ends of girders.

- – The bridge deck has minimum thickness of 175mm made of cast-in-situ reinforced concrete. The continuous thermal plates are of cast-in-situ concrete separated with the girder head concrete by 20mm-thick elastic cushion. Continuous thermal plates are arranged at pier head to ensure the smoothness for vehicles during the bridge operation. Comb expansion joints are arranged at piers T48, T55 and T61 to separate span groups.

* Substructure

- – Piers from T56 to T62: in the form of double rectangular solid frames with rounded corners for aesthetics, size 3.5m x 1.8m. A pier is placed on a foundation of RC bored piles D=1.2m. Pile end rests on weathered rock layer, tentative pile length L= 37m-:-54m depending on location of each pier. The official length shall be decided after trial bored pile at site. Foundation grid, pier shaft, pier cap, bearing base are of cast-in-situ reinforced concrete 35MPa.

- – Piers from T49 to T55: in the form of double rectangular hollow frames with rounded corners for aesthetics, size 3.5m x 2.2m, wall thickness 0.55m. Lateral bracings 2 x 2.2m are arranged in the middle of pier to enhance the stability. A solid pier is placed on a foundation of RC bored piles D=1.2m. Pile end rests on weathered rock layer, tentative pile length L= 40m-:-52m depending on location of each pier. The official length shall be decided after trial bored pile at site. Foundation grid, pier shaft, pier cap, bearing base are of cast-in-situ reinforced concrete 35MPa.

- – Piers from T41 to T48: in the form of double rectangular hollow frames with rounded corners for aesthetics, size 3.5m x 2.2m, wall thickness 0.55m. Lateral bracings 2 x 2.8m are arranged in the middle of pier to enhance the stability. A solid pier is placed on a foundation of RC bored piles D=1.2m. Pile end rests on weathered rock layer, tentative pile length L= 42m-:-51m depending on location of each pier. The official length shall be decided after trial bored pile at site. Foundation grid, pier shaft, pier cap, bearing base are of cast-in-situ reinforced concrete 35MPa.

- – Holes of bored piles are made by a specialized bored pile drilling machine. During pile drilling, use steel casing pipe lowered through weak soil layer. Stabilize pile wall with steel casing pipe and bentonite mortar.

- – The pile length is from the foundation bottom to the pile end.

- – The pile length in the document is tentative. The official pile length shall be decided at site after there are site geological reference drilling results and load-bearing test results using the large-strain dynamic test method.

- – Because the piles are embedded in the rock, the construction unit must choose a drill with high torque, suitable for geological conditions so that the pile drilling is convenient and the piles are drilled to the design elevation.

- – Checking the quality of bored piles

+ The quality of all bored piles are tested by ultrasonic method. In a foundation, 02 piles must be core tested to determine the concrete strength of the pile and drill to check the sawdust at the bottom of the borehole. If the sawdust thickness at the bottom of the borehole does not meet the requirements, the drill bit sawdust must be blown clean and the mortar must be pressed.

+ PDA test: the test shall be carried out at piers T42, T51 and T59.

VNCN E&C has mobilized manpower and equipment to speed up the progress of the Package, ensuring the Project schedule. When Phuoc An bridge is complete, it will help enhance the development and effective operation of the Sea port group No. 4 system, Cai Mep logistics service center, industrial zones along the alignment and different projects in the area. At the same time, it will promote the socio-economic development of the two provinces having the project in particular and of the region in general.

Tiếng Việt

Tiếng Việt

English

English