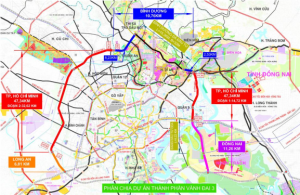

The major economic region in the South including Ho Chi Minh City and the provinces of Dong Nai, Binh Duong, Binh Phuoc, Tay Ninh, Long An, Tien Giang an Ba Ria – Vung Tau is an important region which has a significant contribution to the national socio-economic development. The Government identifies that the Southern major economic region holds the leading role in the sustainable development of the national economy.

Nevertheless, the Southern major economic region has got an obstruction caused by the un-developed transportation which does not meet the demand, the high logistic cost and the traffic jams in urban areas, especially Ho Chi Minh City. The bottlenecks in the connection and the transport infrastructure of the region have been foreseen for years. However, the level of changing situation has not been in line with expectation. Therefore, it is really important to continue and enhance the investment in transport infrastructures, especially the ring roads of Ho Chi Minh City, that will promote the economic growth of Ho Chi Minh City and the provinces of Dong Nai, Binh Duong and Long An, the Southern major economic region in particular and the national economy in general, contributing to improve the competitive capability of the economy.

The Ho Chi Minh City Ring Road No. 3 Construction Investment Project was approved at Resolution No. 57/2022/QH15 dated 16 June 2022.

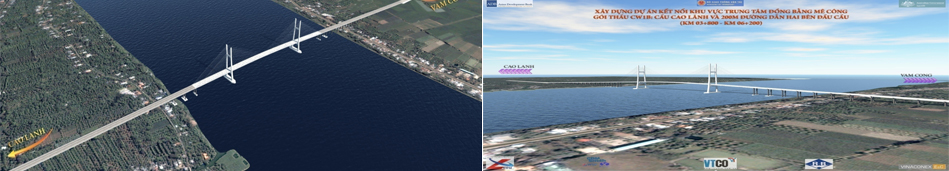

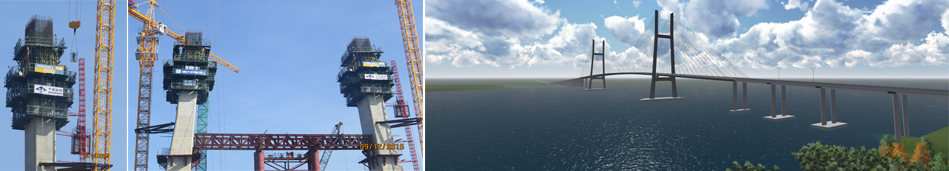

The general alignment of Ho Chi Minh City Ring Road No. 3 Project as per Resolution No. 57/2022/QH15

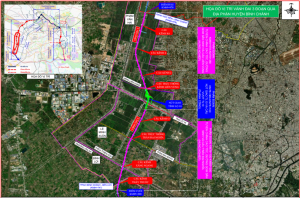

Outline of the alignment through Binh Chanh district, Ho Chi Minh City

Package XL09: Construction of Ring Road No. 3 Binh Chanh district Section (from Km69+978 to Km78+100) is one part of Project Component 1: Construction of Ring Road No. 3 Ho Chi Minh City Section (including Kenh Thay Thuoc bridge) under Ho Chi Minh City Ring Road No. 3 Construction Investment Project has the following scale:

- – Type of works: Road transport works.

- – Class of works:

- + Main route and interchanges: Highway, class I;

- + Bridges (flyovers, bridges over canals or channels): Road bridge, class II;

Main contractor: Joint Venture of VNCN Engineering Construction and Investment Joint Stock Corporation – Hai Dang Joint Stock Company – Hong An Road and Bridge Construction Service Trade Company Limited – 236 Traffic Project Construction and Management Joint Stock Company – Material Equipment and Civil Engineering Joint Stock Company 624 was awarded Package XL09: Construction of Ring Road No. 3 Binh Chanh district Section (from Km69+978 to Km78+100) with the value of VND 2,258 billion. The package will be implemented in 33 months.

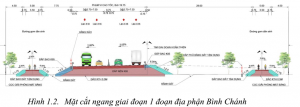

The scale in Phase 1 and technical specifications of main works of the project: Construction of 04 motorized lanes and discontinuous local frontage roads along two sides of the main road. The exploitation velocity in Phase I is V= 80km/h. The cross section of the road is as below:

- – Cross section of the main road:

| + Carriageway | 4×3.75m |

| + Median strip | 1×0.75m |

| + Safety strip adjacent to the median strip | 2×0.75m |

| + Consolidated shoulder | 2×0.75m |

| + Unconsolidated shoulder | 2×0.5m |

Total: 19.75m

- Cross section of local road (for one side):

| + Carriageway | 1×3.5m |

| + Unconsolidated shoulder | 2×0.75m |

Total: 5.00m

Figure 1.2. Road cross sections in Phase 1 for Binh Chanh district section

- . Road embankment and pavement

Pavement structure: According to Standard TCCS 38:2022/TCDBVN, specifically:

- – Expressway: Highway type A1, elasticity modulus E ≥ 205 Mpa;

- – Local frontage road: Highway type A2, elasticity modulus E ≥80 Mpa;

- – Ramps of Provincial Road No. 10 Interchange: Highway type A1, elasticity modulus E≥ 180 Mpa;

- – Kenh Lien Vung bridge approach: Highway type A2, elasticity modulus E≥ 135 Mpa;

Embankment of expressway: Filling with sand at density K98 (capping layer). The other part of the embankment is filled with sand at density K95 (advanced compacted according to Standard 22TCN 333:06). A geo-textile layer is spread between the filling embankment and the natural road bed.

Embankment of local frontage road: Filling with sand at K95 (capping layer). The other part of the embankment is filled with sand at density K90 (advanced compacted according to Standard 22TCN 333:06). A geo-textile layer is spread between the filling embankment and the natural road bed.

Depending on the soft soil depth, the filling height, technical specifications and the Project schedule, the soft soil treatment methods will be: Load reduction floor, cement deep mixing column (according to Standard TCVN 9403:2012), vacuum consolidation method (according to Standard TCVN 9842:2013), prefabrication vertical drain (according to Standard TCVN 9355:2012), etc.

- Bridge work

There are 6 bridges on the alignment including Kenh 6, Kenh 4, Kenh 2, Kenh Lien Vung bridges, Provincial Road No. 10 interchange and Provincial Road No. 10 overpass to be built permanent with reinforced concrete and pre-stressed reinforced concrete.

The Provincial Road No. 10 interchange will be in a trumpet shape, including 1 main route, 5 ramps and 2 flyovers.

- Bridge over canal, channel

| No. | Bridge name | Station | Span outline (m) | Length (m) | Number of abutment pile | Number of pier pile |

| 1 | Kenh 6 | Km71+038 | 12.5 + 18.6 + 12.5 | 48.6 | 33 | 27 |

| 2 | Kenh 4 | Km72+994 | 12.5 + 18.6 + 12.5 | 48.6 | 33 | 27 |

| 3 | Kenh 2 | Km75+294 | 3 x 18.6 | 60.8 | 33 | 30 |

- – Cross section B = 19.75 m.

- – The abutment structure is in “U” shape of cast-in-place reinforced concrete with strength 30 Mpa. The abutment is placed on a foundation of pre-stressed reinforced concrete piles with strength 80 Mpa, diameter D600 mm, length L = (54 ÷ 64) m.

- – The pier structure is in π shape (double posts) in cast-in-situ reinforced concrete with strength 30 Mpa. The pier is placed on a foundation of pre-stressed RC pipe pile with strength 80 Mpa, diameter D600 mm, length L = (54 ÷ 62) m.

- – The span structure consists of 13 girders in “I” cross section in pre-tensioned reinforced concrete with strength 50MPa; cross beams are of cast-in-situ RC with strength 30 MPa; the bridge deck is of cast-in-situ RC with strength 30 MPa and minimum thickness of 18 cm; absorbent waterproofing spray layer; tack coat standard 0.5 kg/m2; asphalt concrete type 16 of 4 cm thick; tack coat standard 0.5kg/m2; porous asphalt concrete type 12.5 of 4.0 cm thick. The bridge deck has a gradient of 2%, as high as the abutment body and the pier cap.

- – Curbs are made of reinforced concrete having strength 25 Mpa. The bridge surface drainage consists of iron pipe (at intake) and steel pipe (conveying water). Elastomeric bearings and comb plate expansion joints are used

- Provincial Road No. 10 Interchange

| No. | Bridge name | Station | Span outline (m) | Length (m) |

| 1 | Ramp A (Ring Road No. 3 Flyover) |

Km77+100 | 39.1 + 47 + 54 + 47 + 39.1 | 239.4 |

| 2 | PR.10 Flyover

(on main road) |

Km77+656 | 39.1 + 11×40 + 39.1 | 524.3 |

- – The breadth of Ramp A is 13.5 m.

- – The breadth of PR.10 flyover is 19.75 m.

- – The abutment structure is in “U” shape, of cast-in-place RC with strength 30 Mpa, placed on a foundation of bored piles with strength 30 Mpa, diameter D1200 mm, tentative length L = (61 ÷ 64) m;

- – Structure of ramp A’s piers:

- + Structure of pier T1 and pier T4: in π shape (double posts) of cast-in-situ reinforced concrete with strength 30 MPa; placed on bored piles foundation with strength 30 Mpa, diameter D1200mm, tentative length L = 63 m; + Structure of pier T2 and pier T3: in V shape of cast-in-situ reinforced concrete with strength 30MPa; placed on bored piles foundation with strength 30 Mpa, diameter D1200mm, tentative length L = (63 ÷ 66) m;

- – Structure of piers of PR.10 Flyover: Narrow solid post pattern (in “T” shape) of cast-in-situ reinforced concrete, pier cap having strength 40 MPa, pier shaft and pier footing having strength 30 MPa; placed on bored piles foundation with strength 30 Mpa, diameter D1200 mm, tentative length L =(55 ÷65) m; for pier caps, use 8 post-tensioned cables, each made of 15 strands of 15.2 mm;

- – The cross section of ramp A span consists of 6 pre-stressed reinforced concrete super T girders having strength 50 MPa; The cross section of PR.10 flyover span consists of 8 pre-stressed reinforced concrete super T girders having strength 50 MPa;

- – Cross beams are cast-in-situ RC with strength 35 MPa; Deck slabs are cast-in-situ RC with strength 35 MPa of minimum 18cm thick; absorbent waterproofing spray layer;

- – Curbs are RC with strength 25 MPa; the bridge surface drainage uses cast iron pipe (at intake) combined with steel pipe (conduit); pot bearings and comb expansion joints are used

VNCN E&C will implement the main road and frontage road of section from Km75+840 to Km78+100 (exluding box culverts and pipe culverts) and 5 bridges consisting Kenh 6 (Km71+038); Kenh 4 (Km72+944); Kenh 2 (Km75+294); Provincial Road No. 10 interchange (Km77+100) and Provincial Road No. 10 Flyover (Km77+656).

Tiếng Việt

Tiếng Việt

English

English